Laser cutting is a technology that has revolutionized the manufacturing industry. It is a precise and efficient cutting process that has a wide range of applications in various industries. Laser cutters are used to cut, engrave, and mark a variety of materials, including metals, plastics, wood, and more. In this article, we will explore the technology behind laser cutters and how they work.

What is a Laser Cutter?

A laser cutter is a computer-controlled cutting machine that uses a high-powered laser beam to cut through materials. The laser beam is directed by mirrors and focused by a lens, which allows the laser to cut through materials with extreme precision and accuracy.

The laser beam used in laser cutting is produced by exciting a gas, such as carbon dioxide or nitrogen, or by using a solid-state laser. The beam is then directed by mirrors to the cutting head, where it is focused onto the material being cut.

How Does a Laser Cutter Work?

The process of laser cutting involves several steps. Here is a brief overview of how a laser cutter works:

1. Design: The first step in laser cutting is designing the part or component that needs to be cut. This is done using computer-aided design (CAD) software, which creates a digital 3D model of the part.

2. Preparation: Once the part is designed, it is loaded into the laser cutter’s software, which creates a cutting path for the laser beam to follow. This path is based on the 3D model of the part and takes into account the thickness and type of material being cut.

3. Calibration: Before cutting, the laser cutter must be calibrated to ensure that the laser beam is aligned and focused correctly. This is done by adjusting the mirrors and lens in the cutting head.

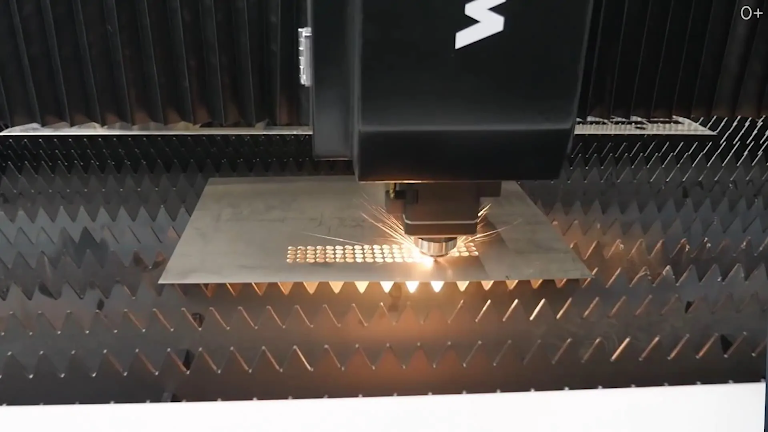

4. Cutting: Once calibrated, the laser cutter begins cutting the material. The laser beam follows the cutting path created by the software, which directs the beam’s intensity and speed. The laser cutter may also use compressed air or another gas to blow away the debris as it cuts.

5. Finishing: After cutting, the part may require finishing, such as smoothing rough edges or adding surface texture. This is done using post-processing techniques, such as sanding or polishing.

Types of Laser Cutters

There are several types of laser cutters, each with its own strengths and weaknesses. Here are the most common types of laser cutters:

1. CO2 laser cutters: These use a gas laser to produce a high-powered beam of infrared light. They are best suited for cutting non-metallic materials, such as acrylic, wood, and paper.

2. Fiber laser cutters: These use a solid-state laser to produce a high-powered beam of light. They are best suited for cutting metallic materials, such as stainless steel, aluminum, and brass.

3. YAG laser cutters: These use a crystal laser to produce a high-powered beam of light. They are best suited for cutting thin metals and ceramics.

Applications of Laser Cutters

Laser cutters are used in a variety of industries, including automotive, aerospace, electronics, and more. Here are some common applications of laser cutters:

1. Fabrication: Laser cutters are used to cut and shape sheet metal and other materials to create complex components and structures.

2. Engraving: Laser cutters can be used to engrave logos, designs, and other graphics onto a variety of materials, such as glass, wood, and plastic.

3. Prototyping: Laser cutters are used to create prototypes of new products and components quickly and accurately.

Conclusion:

Laser cutters are an essential tool for many industries, offering a precise and efficient cutting process that allows for the creation of complex components and structures. Understanding the technology behind laser cutters is crucial to fully appreciate their capabilities and potential applications. You can find a wide range of metal laser cutters here as technology continues to evolve, laser cutters are likely to become even more versatile and efficient, paving the way for new innovations and advancements in manufacturing.